CONÓCENOS

Sobre Nosotros

Fruto de un ambicioso proyecto empresarial con vocación de liderazgo internacional y de la mano de dos líderes de la industria alimentaria a nivel mundial, nace en el año 2016 InLeit Ingredients. Una alianza comercial desarrollada con el fin de convertir a InLeit en un referente mundial en la producción y distribución de ingredientes de alto valor añadido a partir de la leche.

Procesos Tecnológicos

Nuestro expertise en tecnología láctea y una amplia visión del negocio nos han permitido conseguir un proceso de fabricación único

Capacidad Industrial

Nuestra factoría tiene capacidad para procesar 500 millones de litros de leche al año y tecnología de última generación para producir proteínas premium y personalizadas

Certificaciones

Kosher

Halal

Medio Ambiente

InLeit apuesta por el aprovechamiento y valorización de toda la cadena de producción para reducir los residuos generados en su actividad

Seguridad

Nuestras instalaciones garantizan el cumplimiento de todos los estándares y requisitos de calidad, seguridad alimentaria y nutricional

PROCESOS TECNOLÓGICOS

Calidad y Procesos

Obtenemos la mejor materia prima de las ganaderías gallegas y tras someterla a un tratamiento natural, extraemos proteínas lácteas con las que elaboramos productos de alto valor añadido con una gran variedad de aplicaciones en la industria alimentaria.

INNOVACIÓN

InLeit Innovación

Soporte al cliente

Contamos con un equipo altamente profesionalizado y multidisciplinar, siempre dispuesto a desarrollar soluciones innovadoras adaptadas a las necesidades de nuestros clientes.

Soluciones a medida

Las diversas aplicaciones de nuestros productos permiten aportar soluciones para mejorar el perfil nutricional, la textura, la vida útil o la rentabilidad de los productos de nuestros clientes.

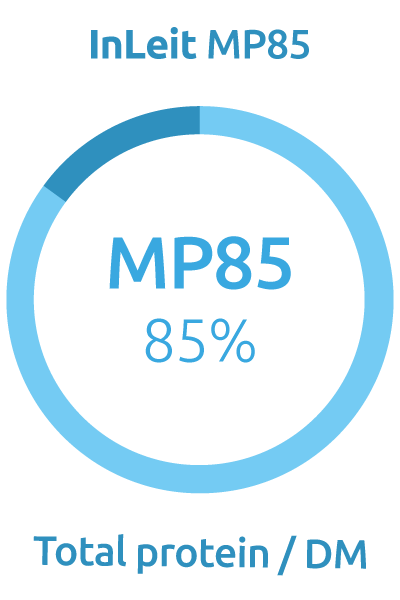

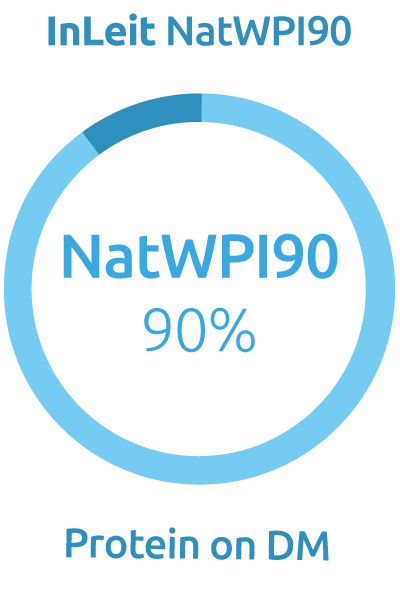

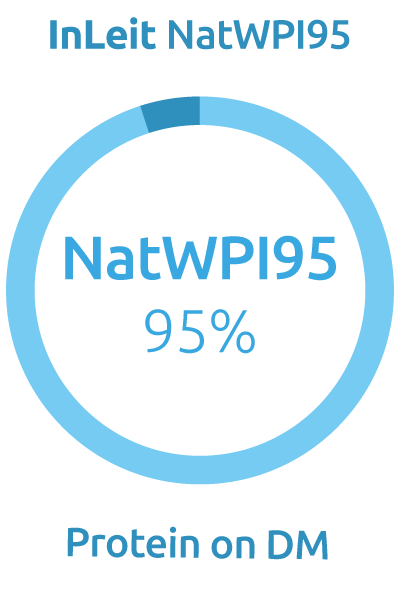

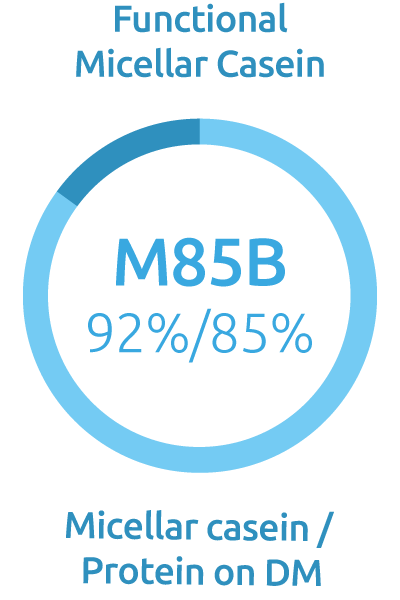

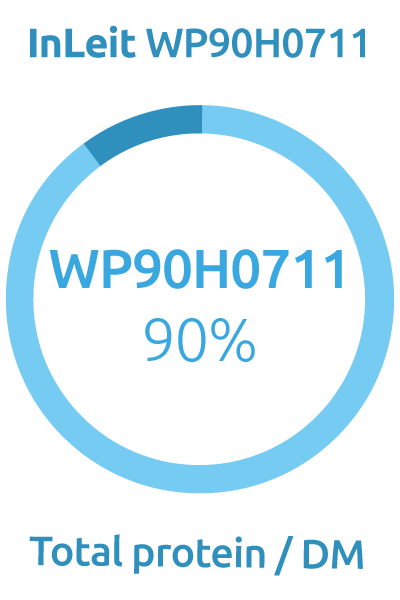

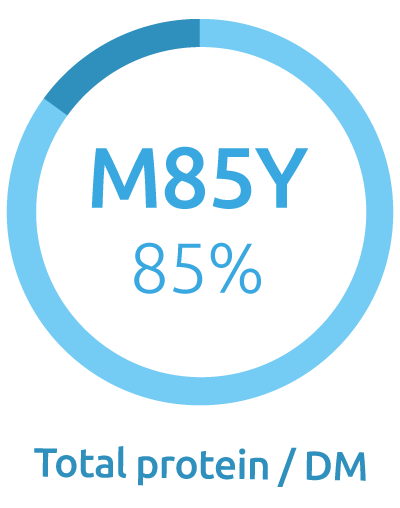

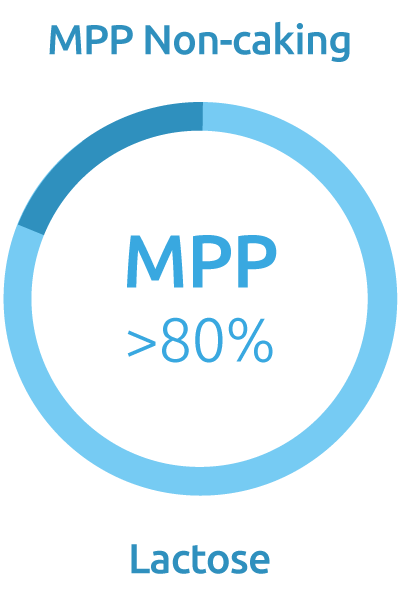

PRODUCTOS

Nuestros Productos y Aplicaciones

Desarrollamos ingredientes de alto valor añadido con un amplio abanico de aplicaciones eficaces en todos los mercados: Desde la nutrición infantil y el desarrollo de suplementos terapéuticos hasta la industria láctea o la nutrición deportiva.

ACTUALIDAD

Últimas Noticias

Filter

CONTACTA

Formulario de Contacto

Por favor, selecciona el tipo de contacto que quieres establecer con InLeit y solicita más información sobre nosotros, nuestros productos o el estado de nuestro trabajo rellenando el formulario.