The cheese industry is experiencing a shift towards more sustainable and efficient practices, which are becoming as important as taste and texture. In the past, the process of making a certain cheese, like camembert, brie, and cream cheese, has been criticized for generating a substantial amount of waste, largely due to the whey separation step. In 2021, Europe produced almost 161 million tons of milk and most of the milk volume has been expelled as whey, resulting in 56.9 million tons of liquid whey1.

Although not a new breakthrough, the adoption of micellar casein is gaining momentum. This process, which circumvents the whey separation, is eco-friendlier and reduces production costs. It represents a maturing technology that continues to grow, reflecting the cheese industry’s evolving commitment to sustainability.

Embracing sustainability with matured technology

To refine the cheese-making process while addressing environmental concerns, innovative techniques utilizing specialized protein blends are being implemented. These methods involve creating a stable, emulsified pre-cheese mixture. This is achieved by mixing water, fats, and protein concentrates, followed by emulsification and homogenization at controlled temperatures and shear rates. The process enhances the viscosity and results in a glossy, white pre-cheese base, which then undergoes high-temperature treatments for microbiological safety.

Furthermore, in regions where dairy resources are scarce, this technique is particularly advantageous. It involves a similar process of emulsification and homogenization, with precise control over temperature and mixing speeds to produce a paste that is then matured, retaining the lactoserum for flavor development. The salting phase is carefully managed, and additional manufacturing aids are introduced to produce cheeses with the desired quality and texture. This approach allows for the production of a variety of cheeses, from soft to hard, tailored to regional preferences, all the while reducing the environmental footprint typically associated with cheese production2,3.

The role of micellar casein

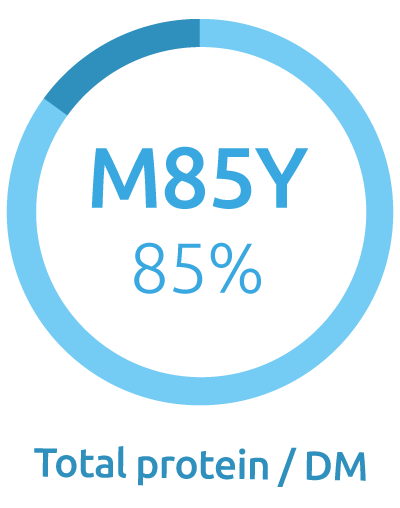

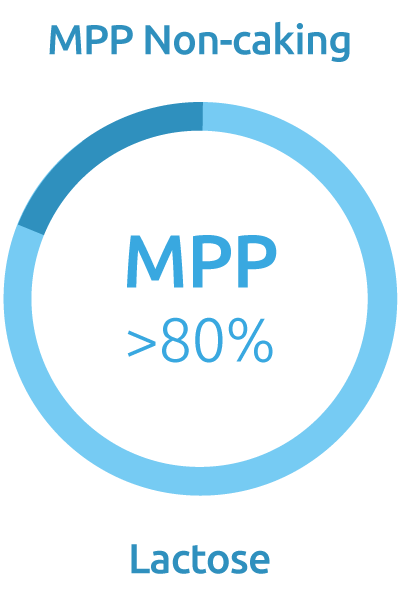

Micellar casein plays an important role in these cheese-making processes. It allows for the production of cheese with a higher protein content and better texture without the need for whey separation. Here’s why:

Micelle structure: Casein proteins are naturally present in milk as micelles, which are clusters capable of carrying a substantial amount of protein in a stable configuration. This is vital for cheese production because it allows the casein to form a gel-like matrix, the foundational element of cheese curd, when it reacts to enzymes or acidification.

Water retention: Thanks to its remarkable water-binding properties, micellar casein can help maintain moisture within the cheese structure. This is especially crucial for producing cheeses with a creamy texture, such as cream cheese, because it allows for a higher moisture content without the necessity of whey extraction.

Heat stability: The heat-resistant nature of micellar casein means it can withstand high temperatures without denaturing. This quality is advantageous for cheese-making processes that involve heat, ensuring that the protein retains its structure and contributes to the desired consistency and body of the final cheese product.

Acid and rennet coagulation: Micellar casein is responsive to both acid and rennet, the agents traditionally used to curdle milk into curds. Its ability to coagulate effectively without separating the whey means that it can form the core structure of the cheese, incorporating all the milk proteins into the curd.

Nutritional profile: Micellar casein is a complete protein, containing all the essential amino acids, which enhances the nutritional value of the cheese. Incorporating more protein directly into the cheese, without losing any to the whey, represents a notable nutritional benefit.

Texture modulation: The functional characteristics of micellar casein allow for the adjustment of cheese texture. Manufacturers can manipulate the concentration and processing conditions to produce a range of textures, from soft and spreadable to firm and sliceable.

Conclusion

The integration of specialized proteins into cheese-making processes is more than a trend; it’s a sustainable evolution in food technology. By eliminating the need for whey separation, these methods address environmental concerns, reduce costs, and open up new possibilities for cheese production. As the industry continues to embrace these innovations, we can expect a new generation of cheeses that are not only delicious but also responsibly made.

References: