Cheese is one of mankind’s first manufactured foods. There is no unanimity on the exact date of its origin, although many studies frame it around 8,000 BC in Mesopotamia. Despite the thousands of years that separate us from that civilization, cheese has managed to remain an article in almost all shopping baskets in much of the world.

Its protein richness (higher and more concentrated than milk) and its ability to pair well with countless foods, has made cheese a star product, both in its most basic presentations and in gourmet quality, where it consumption of cheese occupies the second place of most consumed dairy solids worldwide and, according to the forecasts of the FAO, its consumption per capita will continue to increase in this decade, with the incorporation of new markets such as New Zealand, China, Southwest Asia, among other geographical areas.

In this framework of growth, of a product from which more than 18 million tons are produced annually and with more than 3,000 varieties, the food industry works on new formulas, with greater innovation that allows it to respond to consumer demands, increasingly demanding.

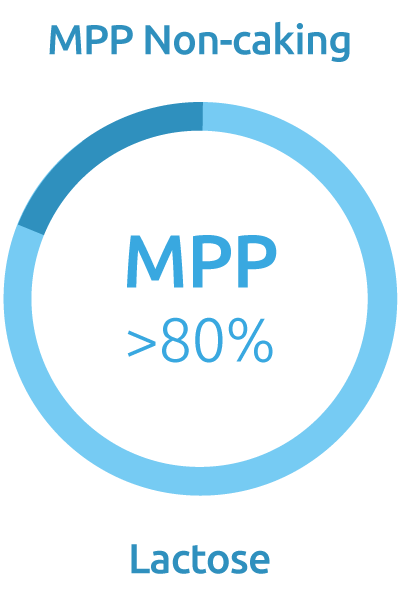

It is here that InLeit milk protein wants to make a difference and offer high-quality, applications for the production of different types of cheese with the best properties, cost-saving, and less industrial investment.

The use of InLeit protein in cheese production has a great interest because its innovative technology simplifies the process and eliminating the main by-product. Sweet or acid whey while maintaining the traditional cheeseproperties: smell, taste, and texture.

We are talking about a process that would no longer need curd cutting,drainage, pressing steps, or whey separation. All this will be possible using the different varieties of functional proteins Leitup range manufactured by InLeit Ingredients.

The question is which type of cheese can we produce with this technology?

Our answer is: Quark (fresh cheese), cream cheese, recombined white cheese (Feta type), soft cheese (Camembert or Brie type), semi-hard cheese (Edam or Gouda type) and soon Pasta Filata type of cheese.

This technology is not just an innovation for production technology, also It can be applied to innovation on shapes of the finished product. The molding/pressing step is replaced by a simple method of product dosage in dedicated molds. Thanks to acidification, coagulation and ripening steps, it will allow us to get very close to the qualities of traditional cheese.

A Rising Market

The incorporation of milk protein in cheese making opens up many possibilities (new varieties, improvements in preservation, and new uses). Some innovations that will be positive for both established producer countries (the United States, with 30% of world production, or France), and for new markets where the consumption and production of cheese are growing.

It is also of interest to those places where there is high consumption but a shortage of milk or fluctuation of milk price, making it difficult for the producer to have cost and profitability estimates.