Our process protects and preserves the natural character of the proteins as much as possible, which allows us to obtain a pure and highly functional protein while preserving all its essence

RAW MATERIAL

100% fresh milk

At InLeit we produce protein ingredients of exceptional quality from 100% fresh milk. We work in permanent contact with selected Galician farms, that provide us the best fresh milk every day. Thanks to this excellent raw material, and to our manufacturing process, we keep all the natural properties of fresh milk intact and produce a unique protein:

- 100% nutrients

- Better taste and smell

- Great texture and solubility

- Maximum functionality and emulsifying quality

Local

We produce in Galicia and we maintain a close collaboration with the farmers, so we always get fresh milk destined only for InLeit, with no surplus from other industries

Comprehensive Monitoring

Our milk is subjected to demanding quality and animal safety checks. We only use Galician milk, hormone and antibiotic free and under strict bacteriological control measures

Daily production

We process the milk immediately upon reception at the factory in a way that its organoleptic qualities are optimum

CAPACITY

InLeit in numbers

500M l per year

Milk processing capacity

17k tons per year

Cream production

16k tons per year

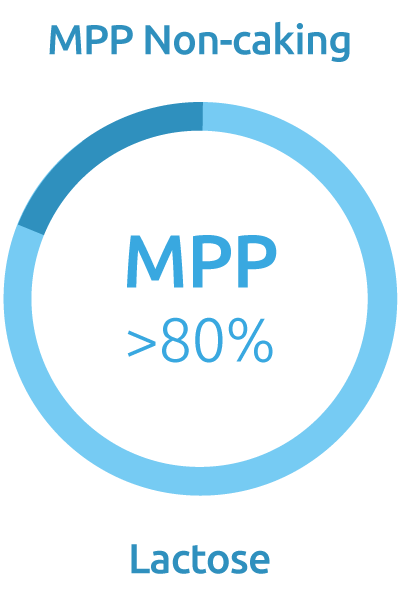

High value protein powder

23k tons per year

Permeate powder

QUALITY

Certificates

KOSHER

HALAL

QUALITY AND PROCESSES

Food Safety

InLeit has state-of-the-art Spray Dryers that allow us to produce premium and customized proteins, in addition to preventing cross contamination.

Our facilities guarantee the quality and safety of the whole production.

Facilities

- Factory built for linear flow

- All factory product storage tanks are pressurized with sterile air to prevent microbial growth and to monitor the air

- Two CIP cleaning stations. One dedicated to the raw products and the other dedicated to pasteurized products

- Air monitoring plan

- Water monitoring plan

Checking of the access area

- Checking of the access area

- Controlled access to the outside of the facilities

- Access control to enter the production area

- Isolated visitors’ room intended for the tour of the production process, that eliminates the possibility of contact with foreign bodies and microorganisms

- Access through the facilities’ CCTVs

Microbiological control

- Physical-chemical and microbiological checks at each stage of the process

- Internal laboratory with the capacity to control DNA pathogens:

- Salmonella / Listeria / C. sakazakii

- Microbiological control by rapid reception test (bacsomatic)

- Hall for access to the interior of the tanks for sampling

Process

- Fully automated process

- There is no direct injection of steam into the product

- Cold organic membrane processes

- Bigbag/bagging solution